Indissoluble bond between intravenous infusion and infusion pump"

Release time:

2021-05-27 10:02

Source:

Www.csbeyond.com

Intravenous infusion is a common way of administration in clinical treatment. In clinical infusion speed may directly affect the therapeutic effect, and may even affect the safety of nursing. Infusion pump is an instrument that can accurately control the number of infusion drops or infusion flow rate, ensure that the drug can play a role in the patient's body with uniform speed, accurate and safe dosage. It is also an intelligent infusion device. The infusion speed is not affected by human back pressure and the operator, and the infusion is accurate and reliable, which helps to reduce the intensity of clinical nursing work and improve the accuracy, safety and quality of infusion.

Infusion pump product model variety, different performance. According to its working characteristics, it can be divided into three categories: peristaltic controlled infusion pump, constant volume controlled infusion pump and syringe micro injection infusion pump.

1. The basic structure and working principle of infusion pump

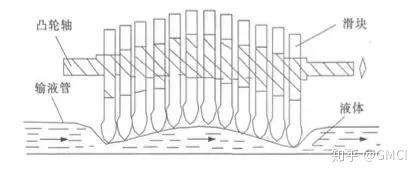

The infusion pump system is mainly composed of microcomputer system, pump device, monitoring device, alarm device and input and display device. The microcomputer system is the "brain" of the whole system. It controls and manages the whole system intelligently, and processes the detection signal. Generally, the single-chip microcomputer system is used. The pump device is the "heart" of the entire system and is the power source for conveying liquids. Medical infusion pumps generally use a finger-shaped peristaltic pump as the power source. Finger peristaltic pump (peristaltic part shown in the figure below) is the use of roller rotation, so that a certain part of the infusion pump pipeline is squeezed, resulting in peristalsis, so as to promote the liquid flow forward. The finger peristaltic pump has the characteristics of small size, light weight, accurate quantification and convenient loading and unloading of infusion tubes, and is the most widely used. This kind of pump has a camshaft, and there are multiple cams on the camshaft. The movement laws of these cams differ by a certain angle. Each cam is connected to a finger slider.

When working, the stepping motor drives the camshaft to rotate, so that the slider moves up and down according to a certain sequence and motion law, squeezing the intravenous infusion tube in turn like a wave, so that the liquid in the infusion tube flows directionally at a certain speed. Finger peristaltic pump is more accurate, and can control the total amount of infusion and infusion speed in a wide range. When the number of "fingers" exceeds 8 (generally 12), the linearity of the pump is good, and it is not easy to produce pulsation during infusion, so that the infusion pump has safety and stability monitoring device mainly consists of a variety of sensors. The infusion pump is equipped with infrared drop sensor, pressure sensor and ultrasonic bubble sensor, etc, they are used for liquid flow rate and flow, clogging pressure and detection of leakage and bubbles, respectively.

The alarm system is the sensor to the signal after processing by the microcomputer, the alarm control signal, and then by the alarm device response, cause people's attention, at the same time the correct processing. It has the function of photoelectric alarm and sound alarm, and can alarm abnormal situations such as power failure, pump door not closed, low temperature, completion of infusion, battery underpressure, pipeline blockage and bubble in pipeline during infusion. The input part of the input and display device is responsible for setting various parameters of infusion, such as infusion volume and infusion speed. The display part is responsible for displaying the parameters and the current working status.

2. Verification and quality control of main performance of infusion pump

In order to ensure the safe and normal operation of the infusion pump and avoid the failure as far as possible, regular testing and quality control must be carried out. According to the JJF1259-2010 "medical injection pump and infusion pump" calibration specification requirements, infusion pump quality testing is mainly divided into electrical safety testing (patient leakage current) and performance testing.

1) Preparation before inspection

The tested instrument should be placed on the workbench (injection pump) or infusion rack (infusion pump) smoothly. The syringe or infusion tube used in the testing process should be compatible with the tested instrument. Generally, the syringe or infusion tube matched with the tested injection pump or infusion pump should be used. The test medium shall be distilled water or deionized water conforming to the requirements of GB/T6682-2008 "Specifications and Test Methods for Analytical Laboratory Water.

2) Leakage current check for patients

The leakage current measurement of patients is divided into external power supply and internal power supply. Fill the infusion pipeline with normal saline (0.9% sodium chloride solution), immerse the output end connected to the patient in a container filled with normal saline, and use the leakage current tester to measure the leakage current of patients between the output end of the infusion pump and the ground of external power supply and between the output end of the infusion pump and the internal power supply respectively. The allowable values of the patient leakage current AC and DC are 0.01mA, respectively.

3) Check the door opening alarm function

During the operation of the infusion pump, if the door is opened without shutdown, the infusion pump shall generate corresponding sound and light alarm.

4) Inspection of bubble alarm function

During the working process of the infusion pump, use a micro-injector to enter bubbles larger than the size specified by the manufacturer in the infusion pipeline. When the bubbles pass through the infusion pump, the infusion pump shall generate corresponding sound and light alarm.

5) Function check of alarm after infusion

Set the infusion volume before the infusion pump works. When the infusion volume reaches the set value, the infusion pump shall stop and alarm.

6) Check the function of power cord falling off alarm

Connect the infusion pump (with built-in power supply or standby power supply) to AC power supply, and the instrument is in the working state of AC power supply. At this time, disconnect the power cord, and it should be able to automatically switch the built-in power supply or standby power supply and give an alarm.

7) Detection of flow metering characteristics

Infusion pump detector is generally used for flow detection. Connect the infusion tube to the injector (when the syringe pump is calibrated) or the infusion tube to the reservoir (when the infusion pump is calibrated), and connect a pipeline to the waste outlet of the detector to introduce the waste liquid into the container. Start the tester and syringe or infusion pump and remove air from the tubing until there are no air bubbles in the tubing. The syringe and infusion tube specified by the syringe pump or infusion pump manufacturer shall be used in the test. Set the flow of the syringe pump or infusion pump as the point to be calibrated, start the tester and the syringe pump or infusion pump again, and wait for the flow reading of the tester to be stable and then record the data. When selecting the calibration point, it should be evenly distributed in the measuring range as far as possible, generally not less than 3 points. It must be noted that the recorded flow is the flow of a given time period, not the instantaneous flow, because the instantaneous flow or the flow in a very short time period is caused by the problem of the structure principle of the equipment. The basic error formula of the flow rate is specific to see the requirements of the calibration specification of the JJF1259-2010 Medical Injection Pumps and Infusion Pumps.

8) Blocking alarm error calibration

The blocking alarm pressure can be measured directly by a detector with blocking alarm test function, or by blocking the infusion line and measuring the blocking pressure by a detector with pressure test. The specific operation method is: set the injection pump or infusion pump to the injection or infusion state. For the former, the detector is set to the test blocking alarm state, so that the infusion of the injection pump or infusion pump is blocked, the injection pump or infusion pump generates corresponding sound and light alarm, and stops the machine. At the same time, the blocking pressure of the detector is recorded. For the latter, the detector is set in the pressure test state and will be blocked by the infusion pipeline of the infusion pump or injection pump until the injection pump or infusion pump generates corresponding sound and light alarm and stops, and the pressure value at the time of alarm is the blocking pressure. The calibrated equipment with multi-level setting blocking alarm shall be measured separately. Refer to the JJF1259-2010 Calibration Specification for Medical Syringe and Infusion Pumps for the block alarm error formula.

Vein, infusion pump, infusion, alarm, injection, detection, work, flow, obstruction, pressure

Previous Page

Next Page

Previous Page

Next Page